|

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | Hi, guys! In this topic, I want to tell you about the turbo project. You may ask: "And how is supercharger?" I will answer. Supercharger very noisy. To me this is not much like it. Once on the American forum Galants, John said to me, make it the turbo. I think it's time to do it. I want to tell you how it's done, how to do a calculation and selection of components. I want to remind you, I don't know English, so I write through the electronic translator. Don't blame much, if something is not clear, you'd better ask about it. So, let's begin... |

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | Many tuners built turbo, then calculated power and etc. However, this is not the right approach. Correctly first, calculate, and then to build the engine. There are a few simple points.

1) Initial settings. (what we have before construction)

2) the Desired result (the one that we want to get)

3) Calculation (we consider the air, fuel, power etc.)

4) Selection of the components (turbine, parts, etc.)

5) Installation (actually Assembly)

6) setup (ECU, pressure, fuel, etc.)

That's it for this scheme will work. |

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | 1)Initial settings. So, what we have? Engine code: 4G69

Size: 2.4 L (2378 QC)

Cylinder: 87 mm

Stroke: 100 mm

Power: 160 HP. (117 kW) at 5750 rpm. with 158 ft·lbf (215 N·m) at 4000 rpm.

Compression ratio : 9,5

MFI fuel injection,

4 valves per cylinder.

Valves without the hydro-compensators.

Automatic gearbox F4A4B.

For the beginning of these parameters are sufficient. |

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | 2) the Desired result.

Oh, this item is always causes a lot of disputes. the voices of the people hundreds of horsepower. But not all people understand that they can use them. You can build any engine. And 400, and 500, and 1000 HP, etc.

However, any increase shall entail significant spending. This relates primarily to the engine itself. Need to strengthen the pistons, rods, gear box, transmission, etc. The total amount of construction is increasing to infinity. Therefore, we must descend from the heavens to the earth and calculate what you can do. |

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | If you leave the stock parts, we can boldly say - 100 HP per liter volume. Go back to step 1. The volume of 2378cc. Thus, the safe capacity will reach 238 hp. A further increase will require strengthening of the engine and the transmission.

However, if the purpose of the project is to leave all part of the stock, then there is another option. This is the performance of the injectors. There are formulas for calculating the performance. They take into account the number of cylinders, pressure fuel pump, duty cycle,the losses of fuel (B.S.F.C.). However, I want to offer another, more simple way.

If the duty cycle is equal to 90%, fuel rail pressure of 3 bar.

The power can be calculated as: the Size of the injector : 5.25 x number of cylinders.

Stock size GS injector = 275 cc.

275 : 5.25 x 4 = 209.5

Thus, the stock injectors, will be able to secure the capacity of 210 HP.

That is, if you take the injectors for example from 6G75 = 305cc. 305 : 5.25 x 4 = 232 HP. |

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | You think 210 HP is very little? Believe me, it will be a very fast car. Is much faster than a stock V6. Because it is important not only power as such. We must take into account the weight of the vehicle and a gear ratio gearbox. I stopped at the power of 210 HP.

Now you need to make the calculation of the air. |

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | You first need to calculate basic air flow N/A. This is done by the formula.

Basic air flow = V x rpm x 0.5 x E / 1000000

where, V - volume (cc), rpm - (6000) 0.5 - of 0.5 means that the four-stroke engine air in the cylinder comes only at the time of one turnover of the two. E - filling ratio (0.85). The number of 1000000 serves to convert cc to cubic meters.

2378 x 6000 x 0.5 x 0.85 /1000000 = 6.06 m3/min

This is a basic air flow N/A 4G69 MIVEC engine. Remember this number.

filling ratio for motors without systems (MIVEC, VTEC, VVTi) = 0.8

Edited by stayer 26/7/2012 15:40

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | Now we need to calculate the required pressure. To do this, we use the formula.

Rated power = the initial power x (the boost pressure /atmospheric pressure)

Make an equation.

210 = 160 x ( X / 1 bar)

210 = 160 x X

X = 210 / 160

X = 1.31bar (absolute pressure = atmospheric pressure + boost pressure

For achievement of the power 210 hp need to 0.31 bar (4.5 psi) boost pressure |

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | The next step is the calculation of the air flow with the turbocharged. This is done by the formula

air flow turbo = boost pressure x basic air flow

1.31 x 6.06 = 7.94 m3/min

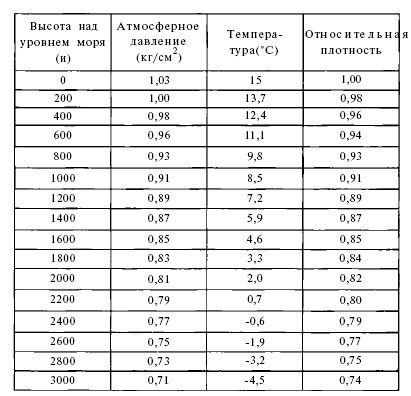

To convert m3/min to a more correct term kg/min, m3/min should be multiplied by the density of the air at a height of geographic location (sorry, inscriptions in Russian)

[IMG]http://i027.radikal.ru/1206/31/1a9886928f55.jpg[/IMG]

(1a9886928f55.jpg) (1a9886928f55.jpg)

Attachments

----------------

1a9886928f55.jpg (35KB - 742 downloads) 1a9886928f55.jpg (35KB - 742 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | Now you can choose a turbocharger. We know the air flow. In the specification of turbochargers is, the parameter of consumption. It is expressed - kg per second. The weight of air per minute / 60 seconds = supply air (It is possible for English it sounds different)

7.94 / 60 = 0.13 kg per second

Now I take the directory and find the desired me turbocharger

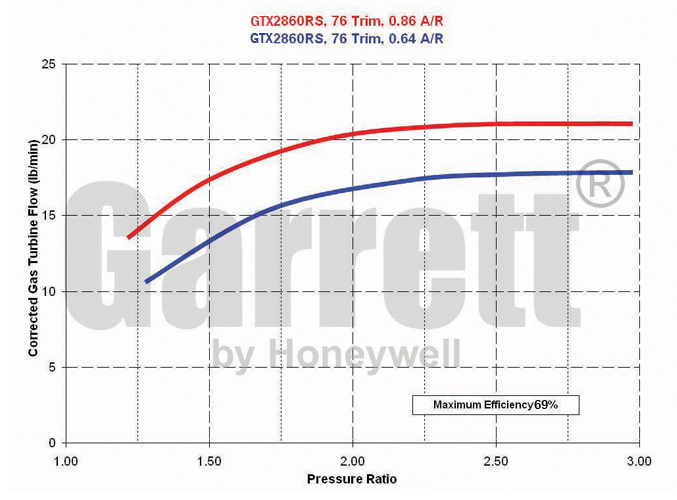

I would like to say that in the metric system measure the speed of the flow kg/s. However, in the directories for the turbo this parameter is specified as lb/min. If you know of pressure and air flow (mass), you can find the turbine. To do this, open directory, for example Garrett Products | Turbochargers

Now you need to select the turbocharger. I translated metric values its turbo. 0.13 kg/s = 17.2lb/min. As you remember absolute pressure = 1.31 bar

Open performance map. We need to find a compressor to the intersection of lines air flow (17.2lb/min) and pressure (1.31 bar), were in the center of the oval.

Thus, if I bought Garrett, then I would chose GT2560R. |

|

| |

|

Frequent flyer Gold

Posts: 1096

Location: An island off southern Tasmania. | Thanks for posting this information.

Don't worry about the language it is fine. |

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | Even some of the members American forums asked me to calculate the engine 6G75MIVEC , to get the 400 HP. This will be retained without change gearbox. I have made a calculation.

Pressure 0.53 bar (7.7psi), Absolute pressure 1.53 bar

Injectors 6 x 360cc

Basic air flow 9.76 kg/min (21.52 lb/min)

Air consumption with the turbo 14.93 kg/min (32.92 lb/min)

Thus, if 1 turbocharger, the optimal choice of GT3582R 1.06A/R

For the application of twin turbo, the optimal choice of 2 turbochargers GT2252

I want to say, the pressure is higher 6psi, requires the use of the cooler. The cooler will take away a portion of the pressure, so when choosing a chargers, pressure is slightly higher than estimated. |

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | This is a very small compressor. This will avoid the lag. It occupies very little space.

(47ce5089cb33.jpg) (47ce5089cb33.jpg)

(ecc37f8ba06c.jpg) (ecc37f8ba06c.jpg)

(1fcac0f2164d.jpg) (1fcac0f2164d.jpg)

Attachments

----------------

47ce5089cb33.jpg (41KB - 641 downloads) 47ce5089cb33.jpg (41KB - 641 downloads)

ecc37f8ba06c.jpg (44KB - 636 downloads) ecc37f8ba06c.jpg (44KB - 636 downloads)

1fcac0f2164d.jpg (53KB - 669 downloads) 1fcac0f2164d.jpg (53KB - 669 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | There is one more option. Compression ratio. The boost pressure is very low. So no change in the engine does not have to. However, I want to give a formula for the calculation.

the total compression ratio = compression ratio + (boost pressure) in square

9.5 + (0.31x0.31) = 9.6

As you can see, nothing will not need to change.

if you calculates high boost pressure, for example 1.5 bar (21psi)

9.5 + (1.5x1.5) = 11.75

in this case it is necessary to reduce the CR. |

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | Turbocharger always have the map. You can see the flow of air on the map. Each charger has its own bandwidth. That is, you can't raise the pressure indefinitely. For example, look at this map. On the left side of the chart, the air flow, pressure from below. As you can see, after 2 bar, the flow is not increased.

(739548-1&064turbweb.jpg) (739548-1&064turbweb.jpg)

Attachments

----------------

739548-1&064turbweb.jpg (196KB - 664 downloads) 739548-1&064turbweb.jpg (196KB - 664 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | At first I wanted to make the exhaust manifold of the stock manifold. Here are a few pics of how it was. But then I had to make another collector.

(a09a3882edfe.jpg) (a09a3882edfe.jpg)

(8b839a4e3a55.jpg) (8b839a4e3a55.jpg)

(0d7593d8e8ae.jpg) (0d7593d8e8ae.jpg)

(7188e086a005.jpg) (7188e086a005.jpg)

Attachments

----------------

a09a3882edfe.jpg (64KB - 675 downloads) a09a3882edfe.jpg (64KB - 675 downloads)

8b839a4e3a55.jpg (56KB - 662 downloads) 8b839a4e3a55.jpg (56KB - 662 downloads)

0d7593d8e8ae.jpg (58KB - 660 downloads) 0d7593d8e8ae.jpg (58KB - 660 downloads)

7188e086a005.jpg (66KB - 806 downloads) 7188e086a005.jpg (66KB - 806 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | However, when I installed the exhaust manifold, he rests in the fan cover. So I decided to make a new exhaust.

(28ff126816f3.jpg) (28ff126816f3.jpg)

(f1bb4a275e78.jpg) (f1bb4a275e78.jpg)

Attachments

----------------

28ff126816f3.jpg (60KB - 677 downloads) 28ff126816f3.jpg (60KB - 677 downloads)

f1bb4a275e78.jpg (61KB - 651 downloads) f1bb4a275e78.jpg (61KB - 651 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | I want to tell you to do as a new exhaust manifold. I bought the elbows and tees from heat-resistant steel (wall thickness 4 mm) And also cut industrial laser 3 parts (12 mm thickness)

To work will require argon welding.

(bd216195bbbb.jpg) (bd216195bbbb.jpg)

Attachments

----------------

bd216195bbbb.jpg (42KB - 771 downloads) bd216195bbbb.jpg (42KB - 771 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | I take tees and doing customized.

Each part of the individual. Therefore, folded the puzzle of the parts are welded argon environment.

(247fb96ba2f0.jpg) (247fb96ba2f0.jpg)

(4a142434028b.jpg) (4a142434028b.jpg)

Attachments

----------------

247fb96ba2f0.jpg (50KB - 664 downloads) 247fb96ba2f0.jpg (50KB - 664 downloads)

4a142434028b.jpg (55KB - 682 downloads) 4a142434028b.jpg (55KB - 682 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | The next stage, to make the flange to the turbocharger. This is done from the tee. You need to cut the middle part of the exhaust manifold.

(d3a1efd17d54.jpg) (d3a1efd17d54.jpg)

(71e39ed5d934.jpg) (71e39ed5d934.jpg)

(19c8c9c1d1cf.jpg) (19c8c9c1d1cf.jpg)

Attachments

----------------

d3a1efd17d54.jpg (69KB - 687 downloads) d3a1efd17d54.jpg (69KB - 687 downloads)

71e39ed5d934.jpg (68KB - 670 downloads) 71e39ed5d934.jpg (68KB - 670 downloads)

19c8c9c1d1cf.jpg (59KB - 660 downloads) 19c8c9c1d1cf.jpg (59KB - 660 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | You can now clear the welding seams.

(c9ac6d2c0ab3.jpg) (c9ac6d2c0ab3.jpg)

Attachments

----------------

c9ac6d2c0ab3.jpg (52KB - 687 downloads) c9ac6d2c0ab3.jpg (52KB - 687 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | And weld flanges. Seams to impose from the inside.

(0d451d544e13.jpg) (0d451d544e13.jpg)

(0e745b74434f.jpg) (0e745b74434f.jpg)

(2cc23d4bbed1.jpg) (2cc23d4bbed1.jpg)

Attachments

----------------

0d451d544e13.jpg (68KB - 675 downloads) 0d451d544e13.jpg (68KB - 675 downloads)

0e745b74434f.jpg (65KB - 658 downloads) 0e745b74434f.jpg (65KB - 658 downloads)

2cc23d4bbed1.jpg (48KB - 673 downloads) 2cc23d4bbed1.jpg (48KB - 673 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | made two slots for O2 sensors.

(eb8fbf331e9c.jpg) (eb8fbf331e9c.jpg)

Attachments

----------------

eb8fbf331e9c.jpg (49KB - 708 downloads) eb8fbf331e9c.jpg (49KB - 708 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | I also want to say that I bought the other turbocharger. It is more suitable for my project. But one must make a remote wastegate valve. On the new turbocharger no valve wastegate. Therefore it is necessary to make external valve. I bought it. Bore diameter of 44 mm. Only after that you can continue the manufacture of exhaust manifold.

(1dfee3e50110.jpg) (1dfee3e50110.jpg)

Attachments

----------------

1dfee3e50110.jpg (46KB - 674 downloads) 1dfee3e50110.jpg (46KB - 674 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | The valve wastegate is very large. He is even more than the turbocharger.

(d56bbf276100.jpg) (d56bbf276100.jpg)

Attachments

----------------

d56bbf276100.jpg (58KB - 685 downloads) d56bbf276100.jpg (58KB - 685 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | Then simply customization.

(d1667cdef51c.jpg) (d1667cdef51c.jpg)

(2a7b411be88e.jpg) (2a7b411be88e.jpg)

(a6ed2da21938.jpg) (a6ed2da21938.jpg)

Attachments

----------------

d1667cdef51c.jpg (51KB - 614 downloads) d1667cdef51c.jpg (51KB - 614 downloads)

2a7b411be88e.jpg (59KB - 670 downloads) 2a7b411be88e.jpg (59KB - 670 downloads)

a6ed2da21938.jpg (54KB - 705 downloads) a6ed2da21938.jpg (54KB - 705 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | I graduated from the welding work. Now we must make the view. For this we need to use blasting. Further milling planes.

(c68bd8fd6b9a.jpg) (c68bd8fd6b9a.jpg)

(f4da529885dc.jpg) (f4da529885dc.jpg)

Attachments

----------------

c68bd8fd6b9a.jpg (59KB - 678 downloads) c68bd8fd6b9a.jpg (59KB - 678 downloads)

f4da529885dc.jpg (54KB - 683 downloads) f4da529885dc.jpg (54KB - 683 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | After sandblasting parts look like this

(01d09af1c21c.jpg) (01d09af1c21c.jpg)

(72cf4c859d4f.jpg) (72cf4c859d4f.jpg)

Attachments

----------------

01d09af1c21c.jpg (45KB - 659 downloads) 01d09af1c21c.jpg (45KB - 659 downloads)

72cf4c859d4f.jpg (48KB - 659 downloads) 72cf4c859d4f.jpg (48KB - 659 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | The next step. Part of the warm up up to 300 C. And dipped in a special acid solution. This gives protection of metal from corrosion and dark in color.

(741ec2beb700.jpg) (741ec2beb700.jpg)

(6059835ef9e2.jpg) (6059835ef9e2.jpg)

Attachments

----------------

741ec2beb700.jpg (35KB - 666 downloads) 741ec2beb700.jpg (35KB - 666 downloads)

6059835ef9e2.jpg (34KB - 660 downloads) 6059835ef9e2.jpg (34KB - 660 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | Now you can mill the surface.

(d283adb7075f.jpg) (d283adb7075f.jpg)

Attachments

----------------

d283adb7075f.jpg (57KB - 657 downloads) d283adb7075f.jpg (57KB - 657 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | Laser logo.

Now the exhaust manifold is ready. You can continue. If you have questions you can ask. Today all.

(402ea77c4254.jpg) (402ea77c4254.jpg)

Attachments

----------------

402ea77c4254.jpg (31KB - 705 downloads) 402ea77c4254.jpg (31KB - 705 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | Soon it will earn in full force. http://www.youtube.com/watch?v=Xj37OSuiOH4&feature=g-upl

Edited by stayer 1/8/2012 19:43

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | I started to do the inlet pipe. The first step, cutting parts in size. Further, the welding works.

(63ee026bd518.jpg) (63ee026bd518.jpg)

(ec18ac4ada8e.jpg) (ec18ac4ada8e.jpg)

Attachments

----------------

63ee026bd518.jpg (34KB - 710 downloads) 63ee026bd518.jpg (34KB - 710 downloads)

ec18ac4ada8e.jpg (61KB - 683 downloads) ec18ac4ada8e.jpg (61KB - 683 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | So it looks like.

(66ebd7f5570b.jpg) (66ebd7f5570b.jpg)

Attachments

----------------

66ebd7f5570b.jpg (77KB - 680 downloads) 66ebd7f5570b.jpg (77KB - 680 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | Now it is necessary to protect the turbocharger.

I bought a blow off valve. Do flanges.

(e86c33f3e487.jpg) (e86c33f3e487.jpg)

(5eaddb6936a7.jpg) (5eaddb6936a7.jpg)

(d197f2ef26e0.jpg) (d197f2ef26e0.jpg)

Attachments

----------------

e86c33f3e487.jpg (47KB - 685 downloads) e86c33f3e487.jpg (47KB - 685 downloads)

5eaddb6936a7.jpg (63KB - 685 downloads) 5eaddb6936a7.jpg (63KB - 685 downloads)

d197f2ef26e0.jpg (78KB - 762 downloads) d197f2ef26e0.jpg (78KB - 762 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | Yesterday killed a whole day to set up. The first attempt failed. Now tell. I wrote a program for the engine. Reflash ECU. Started the engine, everything works. Went to test the car. Immediately, from the first meters of the car very powerfully accelerated. I was very happy. I think we should try to maximum acceleration. Press the pedal to the end. The car breaks off with a squeal of tires. Pressure on the instrument jumps to 14 psi. Then there was a Bang and the engine stalls. Thought that exploded something. Open the hood. Here's what I see. Exploding plastic cover.

(5b3a28a15b7f.jpg) (5b3a28a15b7f.jpg)

Attachments

----------------

5b3a28a15b7f.jpg (54KB - 697 downloads) 5b3a28a15b7f.jpg (54KB - 697 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | I took off the cover. Installed the plug on a rubber tube. And went back again to test the car. Again all is well. The attempt to maximum acceleration. Again something popped and the engine stalls. Open the hood, now I see it. Burst rubber tube.

That's much worse. I had to go to tow up to my repair shop.

Edited by stayer 20/8/2012 20:02

(c5b7666de58d.jpg) (c5b7666de58d.jpg)

Attachments

----------------

c5b7666de58d.jpg (32KB - 676 downloads) c5b7666de58d.jpg (32KB - 676 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | I never give up before the problems. I made metal intake tract. Today again I will adjust the engine, now everything works. Now all.

(d04385d9e9cf.jpg) (d04385d9e9cf.jpg)

Attachments

----------------

d04385d9e9cf.jpg (73KB - 720 downloads) d04385d9e9cf.jpg (73KB - 720 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 516

| Good work.

always the weakest link fails. |

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | Yes, I wanted to maximize the use of OEM parts. However, the safety relief valve was not adjusted and I made a high pressure. |

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | The program for the control of the turbo written. Now you need to make the final look and torque stand. However, not all so is simple. I don't like how that is done at the moment. First of all you should install the intercooler. This will reduce the temperature of the air and increase density. I bought a cooler, but it is still on the way to me. The second task, to make the intake tract before the turbocharger. The thing is that I measured the temperature of the air in the stock air filter and when Dryflow filter.

Result: stock 56C, dryflow 71C. This is an occasion to think, those who establish themselves dryflow filter.

So I decided to make housing for the stock filter. This is what I want today to tell.

The stock filter housing consists of two parts. I need to rotate the housing by 90 degrees. I left that part in which the MAF sensor. The second part is to be made. |

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | I took dimensions and cut metal. Then turned down on bending machine. And carry out welding work.

(4a58cbd8b3db.jpg) (4a58cbd8b3db.jpg)

(45b9be55a95c.jpg) (45b9be55a95c.jpg)

Attachments

----------------

4a58cbd8b3db.jpg (46KB - 671 downloads) 4a58cbd8b3db.jpg (46KB - 671 downloads)

45b9be55a95c.jpg (60KB - 675 downloads) 45b9be55a95c.jpg (60KB - 675 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | Make a box to filter.

(7fad2789bfb1.jpg) (7fad2789bfb1.jpg)

(55f9ef4863f9.jpg) (55f9ef4863f9.jpg)

(257910efad39.jpg) (257910efad39.jpg)

Attachments

----------------

7fad2789bfb1.jpg (58KB - 675 downloads) 7fad2789bfb1.jpg (58KB - 675 downloads)

55f9ef4863f9.jpg (53KB - 688 downloads) 55f9ef4863f9.jpg (53KB - 688 downloads)

257910efad39.jpg (65KB - 681 downloads) 257910efad39.jpg (65KB - 681 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | Now we must make the lower inlet air and discharge of water.

(94e0c68a69b1.jpg) (94e0c68a69b1.jpg)

(0612961fe5a0.jpg) (0612961fe5a0.jpg)

(2987792df6b8.jpg) (2987792df6b8.jpg)

(72de07a1a42f.jpg) (72de07a1a42f.jpg)

Attachments

----------------

94e0c68a69b1.jpg (58KB - 694 downloads) 94e0c68a69b1.jpg (58KB - 694 downloads)

0612961fe5a0.jpg (61KB - 704 downloads) 0612961fe5a0.jpg (61KB - 704 downloads)

2987792df6b8.jpg (62KB - 681 downloads) 2987792df6b8.jpg (62KB - 681 downloads)

72de07a1a42f.jpg (58KB - 682 downloads) 72de07a1a42f.jpg (58KB - 682 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | Then the tube to the air intake.

(59a0ddc1f4bf.jpg) (59a0ddc1f4bf.jpg)

(c051dcaa5e95.jpg) (c051dcaa5e95.jpg)

(a899832b7d55.jpg) (a899832b7d55.jpg)

Attachments

----------------

59a0ddc1f4bf.jpg (37KB - 712 downloads) 59a0ddc1f4bf.jpg (37KB - 712 downloads)

c051dcaa5e95.jpg (45KB - 699 downloads) c051dcaa5e95.jpg (45KB - 699 downloads)

a899832b7d55.jpg (41KB - 711 downloads) a899832b7d55.jpg (41KB - 711 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | I did paint work. Body painted powder paint. So it looks like. Wear a rubber gasket.

(50b54663e717.jpg) (50b54663e717.jpg)

(d6914bddea85.jpg) (d6914bddea85.jpg)

(79b6dbd38aea.jpg) (79b6dbd38aea.jpg)

Attachments

----------------

50b54663e717.jpg (32KB - 668 downloads) 50b54663e717.jpg (32KB - 668 downloads)

d6914bddea85.jpg (33KB - 692 downloads) d6914bddea85.jpg (33KB - 692 downloads)

79b6dbd38aea.jpg (32KB - 642 downloads) 79b6dbd38aea.jpg (32KB - 642 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | The next step manufacture of air intake. Only not finished yet, has left work until Monday. On this day all.

(5dbb31f387ab.jpg) (5dbb31f387ab.jpg)

(3f82bd04b7d7.jpg) (3f82bd04b7d7.jpg)

Attachments

----------------

5dbb31f387ab.jpg (66KB - 686 downloads) 5dbb31f387ab.jpg (66KB - 686 downloads)

3f82bd04b7d7.jpg (58KB - 671 downloads) 3f82bd04b7d7.jpg (58KB - 671 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 516

| Beautiful work. |

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | Little progress. I made the intake air. Then coating powder paint. I chose the color "black silk". It is very pleasant to the touch. Now I'm waiting for the mail interсooler and pipes, as well as silicone hoses.

(fd23186fd4e0.jpg) (fd23186fd4e0.jpg)

(1aa57e528f67.jpg) (1aa57e528f67.jpg)

(17678afef64f.jpg) (17678afef64f.jpg)

(7845893eaa16.jpg) (7845893eaa16.jpg)

Attachments

----------------

fd23186fd4e0.jpg (47KB - 718 downloads) fd23186fd4e0.jpg (47KB - 718 downloads)

1aa57e528f67.jpg (44KB - 685 downloads) 1aa57e528f67.jpg (44KB - 685 downloads)

17678afef64f.jpg (30KB - 694 downloads) 17678afef64f.jpg (30KB - 694 downloads)

7845893eaa16.jpg (26KB - 721 downloads) 7845893eaa16.jpg (26KB - 721 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | I received a parcel. Immediately and set intercoooler.

(09bb2d760aad.jpg) (09bb2d760aad.jpg)

(c99ecb88f88e.jpg) (c99ecb88f88e.jpg)

(19ba2aba26df.jpg) (19ba2aba26df.jpg)

Attachments

----------------

09bb2d760aad.jpg (60KB - 684 downloads) 09bb2d760aad.jpg (60KB - 684 downloads)

c99ecb88f88e.jpg (55KB - 720 downloads) c99ecb88f88e.jpg (55KB - 720 downloads)

19ba2aba26df.jpg (49KB - 663 downloads) 19ba2aba26df.jpg (49KB - 663 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | Operation of the system as a whole. Sorry, explanations in Russian. But I think you will understand the meaning.

Video: http://www.youtube.com/watch?v=OFPuqwFsb-I&feature=g-upl]19092012042 - YouTube |

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | I want to show the video acceleration from a standstill to 100 mph (160 km/h) it is 19 seconds. Just want to say that tune is not final. Finish the tune can be created only on a chassis dyno. It will be later.

http://www.youtube.com/watch?v=7C6goDJxHYU&feature=youtu.be]20092012052 - YouTube

Stock 9G (2.4 l) does the same thing for 29.5 seconds. |

|

| |

|

Frequent flyer Gold

Posts: 286

Location: Russia, Perm | As video acceleration to 100 km/h up to 160 km/h

http://www.youtube.com/watch?v=5C4LiCwqsc0&feature=youtu.be]20092012053 - YouTube

As video acceleration to 0 up to 100 km/h - 6.8 sec

http://www.youtube.com/watch?v=m51rssvdL5g&feature=youtu.be]20092012065 - YouTube |

|

| |

|

Frequent flyer Gold

Posts: 516

| that is nice and fast for a 4 cylinder....good work. |

|

| |

|

Frequent flyer Bronze

Posts: 45

Location: Perth, WA | Some damn good work, that waste gate is huge! |

|

| |

Turbo kit for 4G69

Turbo kit for 4G69 Turbo kit for 4G69

Turbo kit for 4G69