|

|

Frequent flyer Gold

Posts: 1096

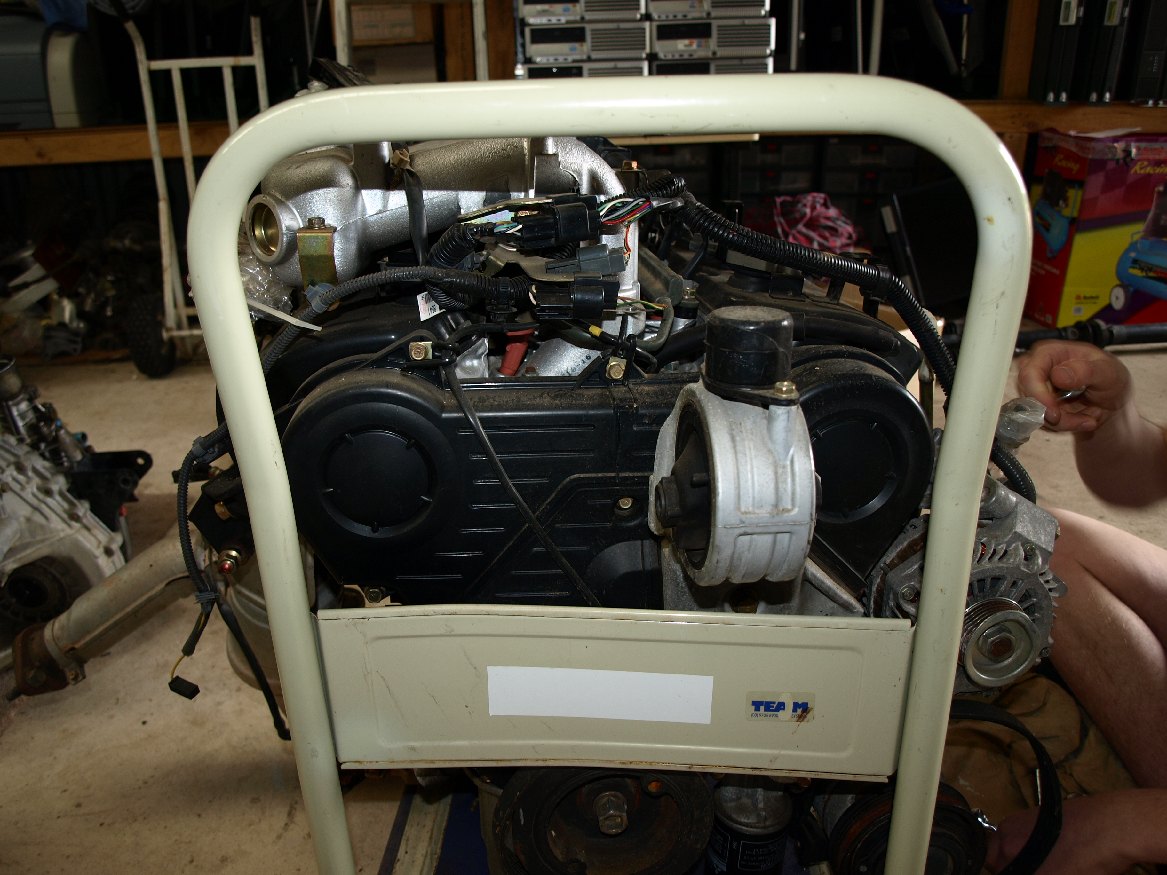

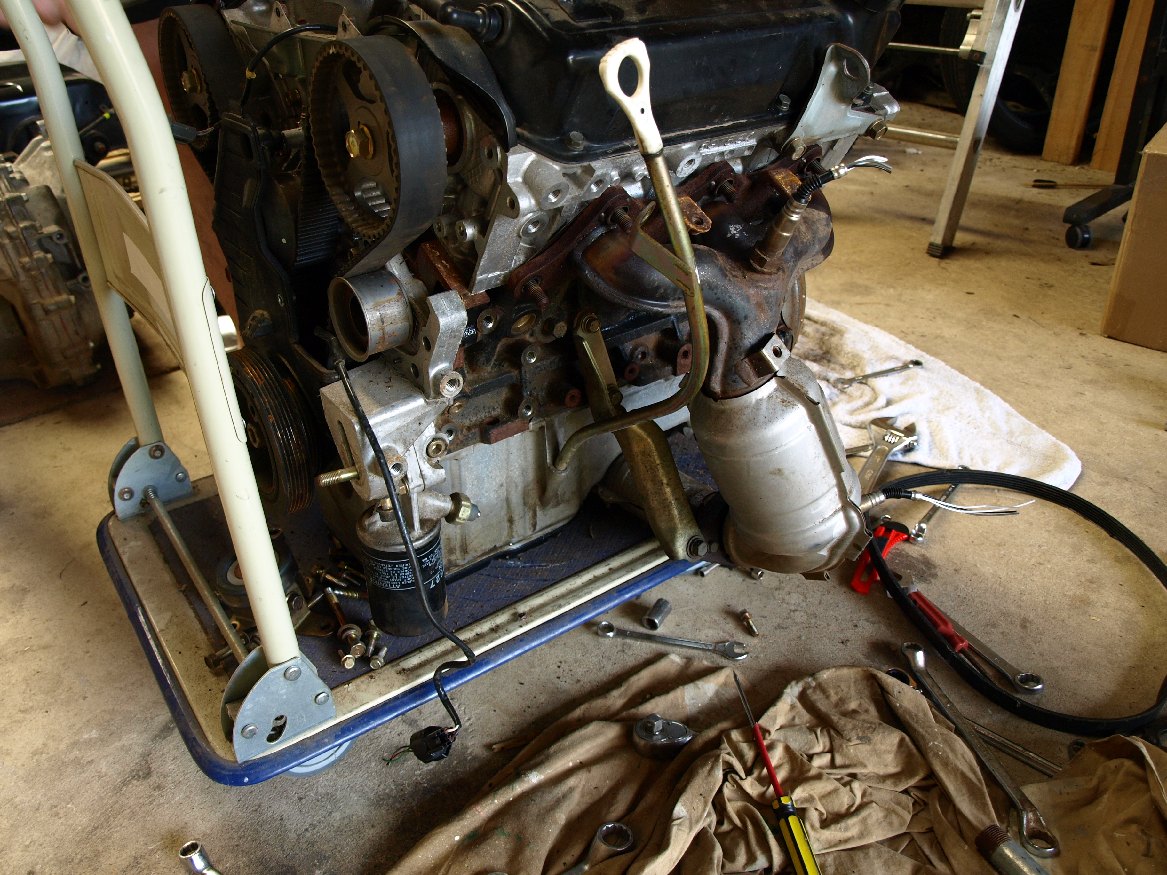

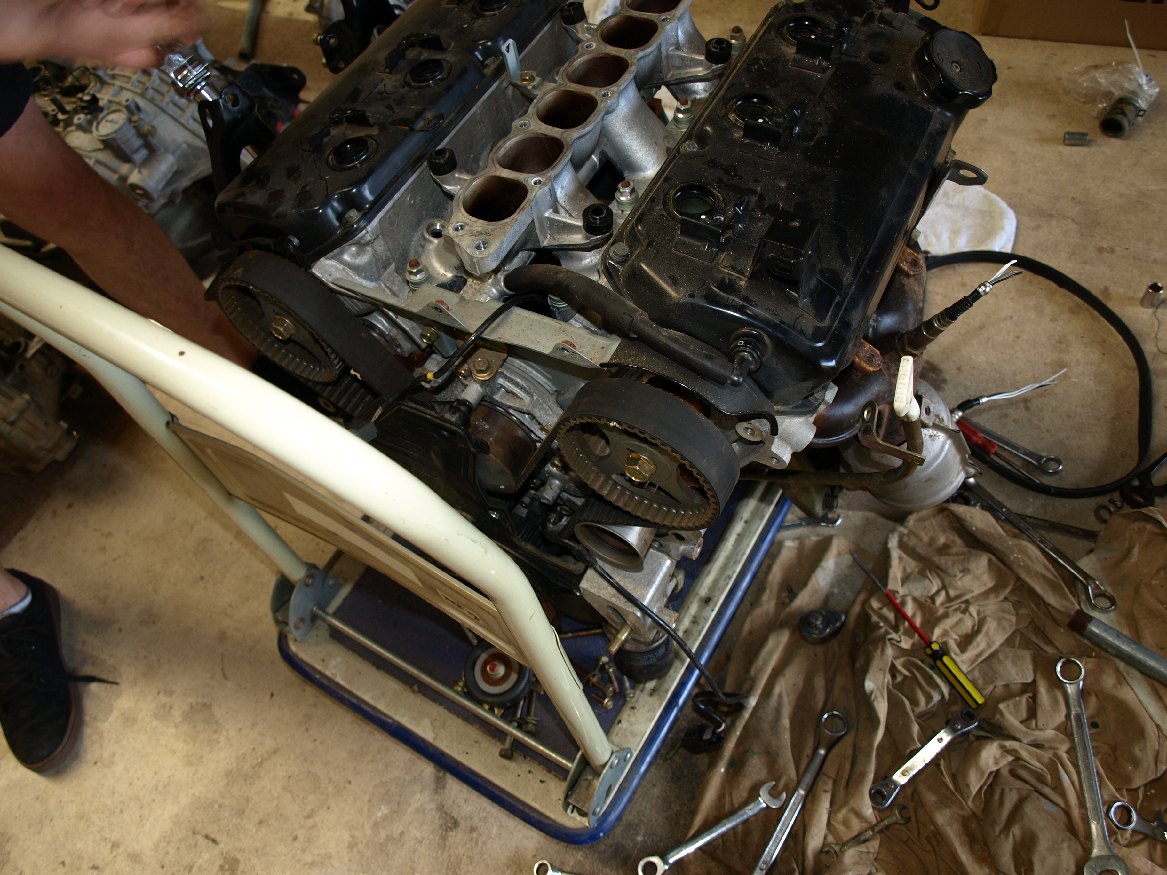

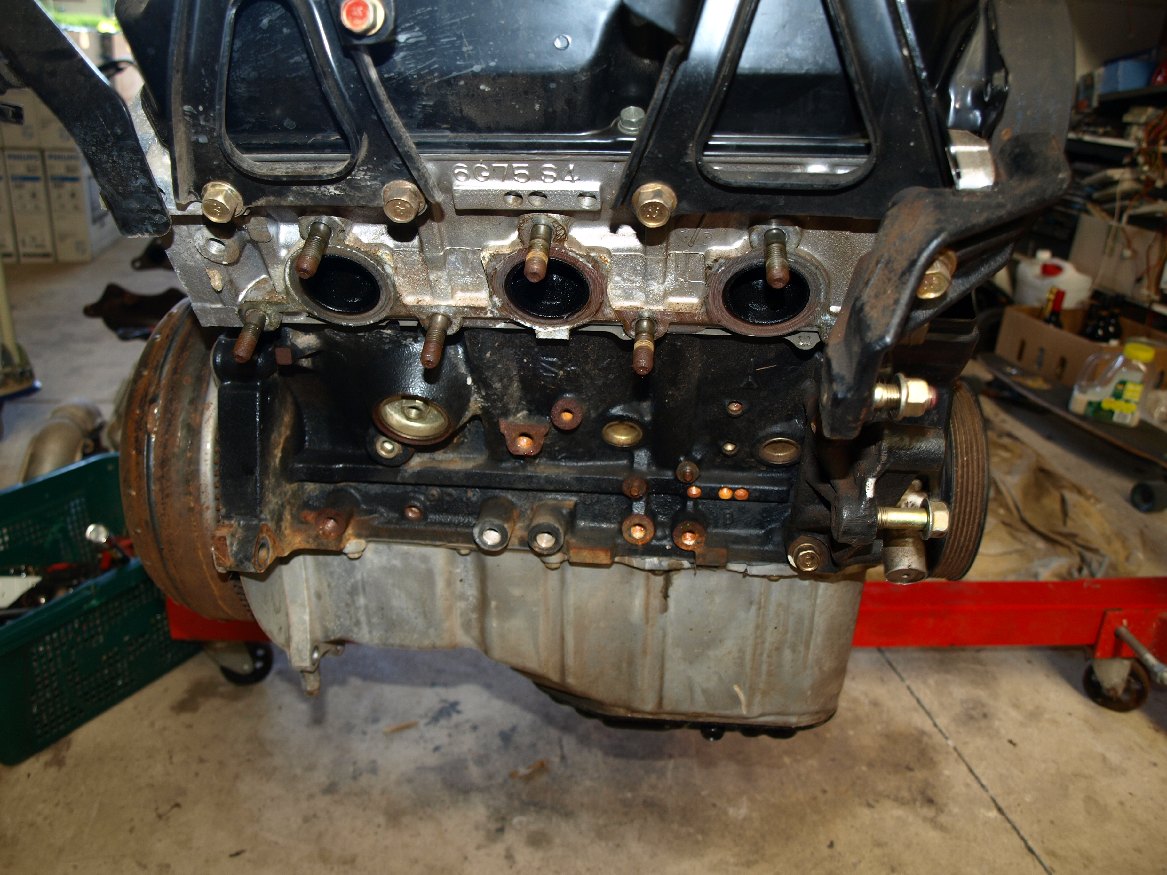

Location: An island off southern Tasmania. | Here are pics of my donor engine to the forged project.

(cooling system under inlet manifold-push fir with o ring.JPG) (cooling system under inlet manifold-push fir with o ring.JPG)

(cracked oil filter mount.JPG) (cracked oil filter mount.JPG)

(crank angle sensor.JPG) (crank angle sensor.JPG)

(crank pulley and bolt-normal thread.JPG) (crank pulley and bolt-normal thread.JPG)

(crank pulley off.JPG) (crank pulley off.JPG)

(engine on trolley before pull down.JPG) (engine on trolley before pull down.JPG)

(exhaust intact 2.JPG) (exhaust intact 2.JPG)

(exhaust intact.JPG) (exhaust intact.JPG)

(firewall side before pull down.JPG) (firewall side before pull down.JPG)

(gotta pull the crank pulley off to get to last bolt holding cover on.JPG) (gotta pull the crank pulley off to get to last bolt holding cover on.JPG)

(hidden timing belt cover screw behind crank pulley.JPG) (hidden timing belt cover screw behind crank pulley.JPG)

(inlet manifold nut spacers.JPG) (inlet manifold nut spacers.JPG)

(knock sensor removed.JPG) (knock sensor removed.JPG)

(knock sensor under inlet manifold.JPG) (knock sensor under inlet manifold.JPG)

(PA090232.JPG) (PA090232.JPG)

(PA090233.JPG) (PA090233.JPG)

(PA090234.JPG) (PA090234.JPG)

(PA090235.JPG) (PA090235.JPG)

(PA090236.JPG) (PA090236.JPG)

(PA090237.JPG) (PA090237.JPG)

(PA090238.JPG) (PA090238.JPG)

(PA090240.JPG) (PA090240.JPG)

(PA090241.JPG) (PA090241.JPG)

(PA090243.JPG) (PA090243.JPG)

(PA090244.JPG) (PA090244.JPG)

(PA100247.JPG) (PA100247.JPG)

(PA100251.JPG) (PA100251.JPG)

(PA100253.JPG) (PA100253.JPG)

(PA100254.JPG) (PA100254.JPG)

(PA100259.JPG) (PA100259.JPG)

(PA100260.JPG) (PA100260.JPG)

(PA100268.JPG) (PA100268.JPG)

(PA100269.JPG) (PA100269.JPG)

(PA100270.JPG) (PA100270.JPG)

(PA100272.JPG) (PA100272.JPG)

(PA100276.JPG) (PA100276.JPG)

(PA100278.JPG) (PA100278.JPG)

(PA100279.JPG) (PA100279.JPG)

(ready to go.JPG) (ready to go.JPG)

(sending to engineworx.JPG) (sending to engineworx.JPG)

(TDC 1.JPG) (TDC 1.JPG)

(TDC 2.JPG) (TDC 2.JPG)

(TDC 3.JPG) (TDC 3.JPG)

(TDC 4.JPG) (TDC 4.JPG)

(three holes in head AND block.JPG) (three holes in head AND block.JPG)

(timing belt layout.JPG) (timing belt layout.JPG)

(transmission end view.JPG) (transmission end view.JPG)

(water in the Vee.JPG) (water in the Vee.JPG)

(wiring loom.JPG) (wiring loom.JPG)

Attachments

----------------

cooling system under inlet manifold-push fir with o ring.JPG (245KB - 834 downloads) cooling system under inlet manifold-push fir with o ring.JPG (245KB - 834 downloads)

cracked oil filter mount.JPG (159KB - 800 downloads) cracked oil filter mount.JPG (159KB - 800 downloads)

crank angle sensor.JPG (302KB - 824 downloads) crank angle sensor.JPG (302KB - 824 downloads)

crank pulley and bolt-normal thread.JPG (244KB - 812 downloads) crank pulley and bolt-normal thread.JPG (244KB - 812 downloads)

crank pulley off.JPG (190KB - 847 downloads) crank pulley off.JPG (190KB - 847 downloads)

engine on trolley before pull down.JPG (220KB - 836 downloads) engine on trolley before pull down.JPG (220KB - 836 downloads)

exhaust intact 2.JPG (218KB - 815 downloads) exhaust intact 2.JPG (218KB - 815 downloads)

exhaust intact.JPG (270KB - 799 downloads) exhaust intact.JPG (270KB - 799 downloads)

firewall side before pull down.JPG (220KB - 833 downloads) firewall side before pull down.JPG (220KB - 833 downloads)

gotta pull the crank pulley off to get to last bolt holding cover on.JPG (223KB - 992 downloads) gotta pull the crank pulley off to get to last bolt holding cover on.JPG (223KB - 992 downloads)

hidden timing belt cover screw behind crank pulley.JPG (146KB - 806 downloads) hidden timing belt cover screw behind crank pulley.JPG (146KB - 806 downloads)

inlet manifold nut spacers.JPG (164KB - 784 downloads) inlet manifold nut spacers.JPG (164KB - 784 downloads)

knock sensor removed.JPG (99KB - 780 downloads) knock sensor removed.JPG (99KB - 780 downloads)

knock sensor under inlet manifold.JPG (247KB - 950 downloads) knock sensor under inlet manifold.JPG (247KB - 950 downloads)

PA090232.JPG (185KB - 861 downloads) PA090232.JPG (185KB - 861 downloads)

PA090233.JPG (209KB - 790 downloads) PA090233.JPG (209KB - 790 downloads)

PA090234.JPG (271KB - 738 downloads) PA090234.JPG (271KB - 738 downloads)

PA090235.JPG (209KB - 773 downloads) PA090235.JPG (209KB - 773 downloads)

PA090236.JPG (250KB - 816 downloads) PA090236.JPG (250KB - 816 downloads)

PA090237.JPG (268KB - 833 downloads) PA090237.JPG (268KB - 833 downloads)

PA090238.JPG (224KB - 798 downloads) PA090238.JPG (224KB - 798 downloads)

PA090240.JPG (221KB - 810 downloads) PA090240.JPG (221KB - 810 downloads)

PA090241.JPG (249KB - 814 downloads) PA090241.JPG (249KB - 814 downloads)

PA090243.JPG (187KB - 879 downloads) PA090243.JPG (187KB - 879 downloads)

PA090244.JPG (182KB - 816 downloads) PA090244.JPG (182KB - 816 downloads)

PA100247.JPG (248KB - 774 downloads) PA100247.JPG (248KB - 774 downloads)

PA100251.JPG (203KB - 843 downloads) PA100251.JPG (203KB - 843 downloads)

PA100253.JPG (236KB - 772 downloads) PA100253.JPG (236KB - 772 downloads)

PA100254.JPG (204KB - 801 downloads) PA100254.JPG (204KB - 801 downloads)

PA100259.JPG (225KB - 793 downloads) PA100259.JPG (225KB - 793 downloads)

PA100260.JPG (203KB - 781 downloads) PA100260.JPG (203KB - 781 downloads)

PA100268.JPG (209KB - 816 downloads) PA100268.JPG (209KB - 816 downloads)

PA100269.JPG (193KB - 827 downloads) PA100269.JPG (193KB - 827 downloads)

PA100270.JPG (167KB - 751 downloads) PA100270.JPG (167KB - 751 downloads)

PA100272.JPG (224KB - 765 downloads) PA100272.JPG (224KB - 765 downloads)

PA100276.JPG (198KB - 841 downloads) PA100276.JPG (198KB - 841 downloads)

PA100278.JPG (140KB - 797 downloads) PA100278.JPG (140KB - 797 downloads)

PA100279.JPG (119KB - 794 downloads) PA100279.JPG (119KB - 794 downloads)

ready to go.JPG (240KB - 833 downloads) ready to go.JPG (240KB - 833 downloads)

sending to engineworx.JPG (205KB - 710 downloads) sending to engineworx.JPG (205KB - 710 downloads)

TDC 1.JPG (159KB - 729 downloads) TDC 1.JPG (159KB - 729 downloads)

TDC 2.JPG (196KB - 750 downloads) TDC 2.JPG (196KB - 750 downloads)

TDC 3.JPG (205KB - 781 downloads) TDC 3.JPG (205KB - 781 downloads)

TDC 4.JPG (220KB - 962 downloads) TDC 4.JPG (220KB - 962 downloads)

three holes in head AND block.JPG (207KB - 758 downloads) three holes in head AND block.JPG (207KB - 758 downloads)

timing belt layout.JPG (224KB - 1541 downloads) timing belt layout.JPG (224KB - 1541 downloads)

transmission end view.JPG (196KB - 757 downloads) transmission end view.JPG (196KB - 757 downloads)

water in the Vee.JPG (255KB - 767 downloads) water in the Vee.JPG (255KB - 767 downloads)

wiring loom.JPG (260KB - 660 downloads) wiring loom.JPG (260KB - 660 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 421

Location: Brisbane,qld | Is it safe to remove the heads on my 75 clean her up and refit???, theres no trick to it |

|

| |

|

Frequent flyer Gold

Posts: 1096

Location: An island off southern Tasmania. | you need a torque wrench.

Loosen the middle bolt, then go clockwise in ever increasing radius till all undone.

Then check stainless steel head gasket edges, they have a rubber type edge, if that's still okay I reuse it.

Torque to 110nm starting at a middle bolt and in an increasing circle torque to 110, back to zero, then back to 110.

Well thats what the book says to do and it worked for me on three engines so far...boosted as well.

Of course before you do all that you need to set up timing belt and align both cams to the notch on the sump and the crank on TDC.

The belt tensioner has a technique as well...you'll need apaper clip and a vice slowly compressing it till the pin hole lines up etc.

Big job mate...probably will not gain you anything me thinks. |

|

| |

|

Frequent flyer Gold

Posts: 421

Location: Brisbane,qld | This is the motor, timing is all good, yeah didnt think i would gain anything other than saying i had done it..lol, i like to pull things apart as long as i can put it back the way it was, only way to learn hey, Advice much appreciated

(2013-02-06 13.10.11.png) (2013-02-06 13.10.11.png)

Attachments

----------------

2013-02-06 13.10.11.png (61KB - 674 downloads) 2013-02-06 13.10.11.png (61KB - 674 downloads)

|

|

| |

|

Frequent flyer Gold

Posts: 1096

Location: An island off southern Tasmania. | they really are a great engine. |

|

| |

|

Frequent flyer Gold

Posts: 1096

Location: An island off southern Tasmania. | Hey mate, just remembered a youtube video I did for a guy about tensioningt head bolts...the slack way...

http://www.youtube.com/watch?v=qIHpuHLDeHU |

|

| |

|

Frequent flyer Gold

Posts: 421

Location: Brisbane,qld | Like the wrench, thanks fot that |

|

| |

6G75 strip down

6G75 strip down 6G75 strip down

6G75 strip down